-

Klaus Gross GmbH & Co. KG in Celle

-

-

Non-Destructive Testing

-

Oilfield Services

We are a service provider for the oil and gas supply industry as well as the metal and mechanical engineering sectors.

Our clients also include customers from the aerospace, power plant construction, energy, defence and many other industries.

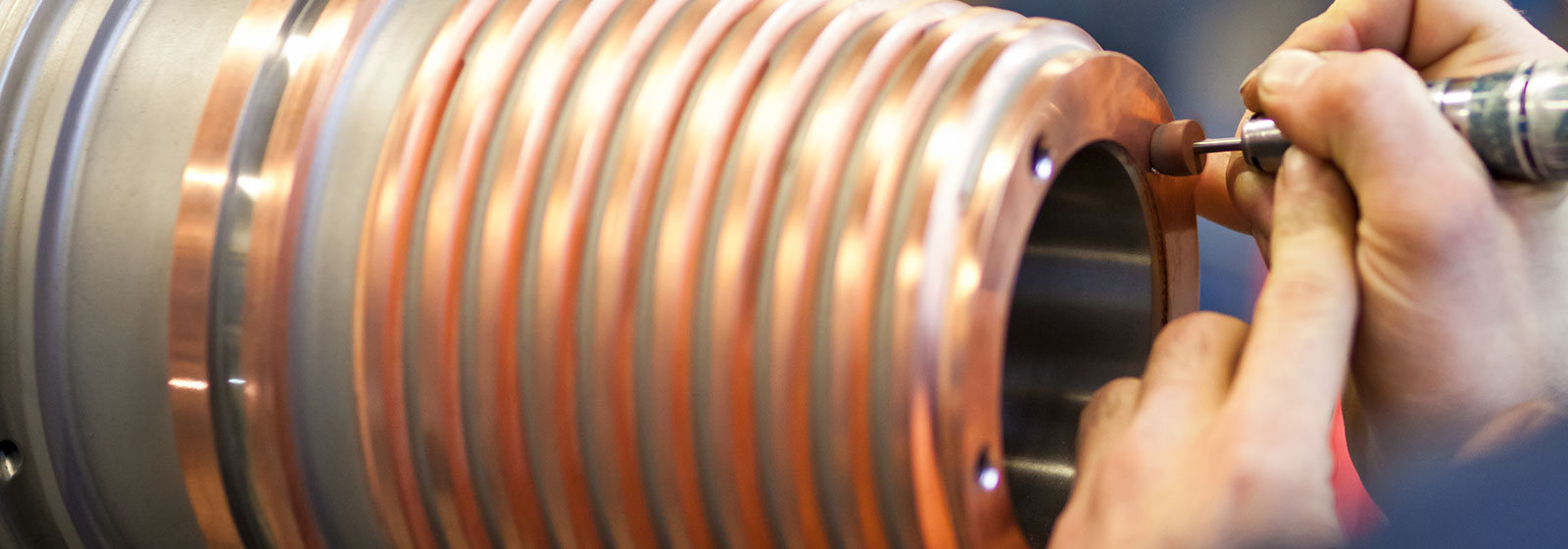

Our company's core competencies are non-destructive material testing, various surface treatment processes such as painting, phosphating, oxilane coating, sandblasting, industrial washing, (ECM) deburring, and, in the field of oilfield services, the reconditioning of drilling motors and rods, straightening and high-pressure water jetting.

Klaus Gross GmbH & Co. KG has been active in non-destructive material testing since its inception, giving us a wealth of experience spanning forty years.

This experience, coupled with great flexibility and highly motivated employees, has always set us apart.

sandstrahlen celle, nasslackieren celle, lackieren celle

Our Phosphating process consists the degreasing of multiple rinse as well as the preactivation and the manganphosphating.

The OXSILAN® process is an environmentally friendly, multi-metal pretreatment technology.

We use sandblasting for cleaning, deburring and smoothing a wide range of materials.

We offer industrial painting for individual parts, small and large series in the highest quality in our painting facility in Celle.

For more than 30 years, Klaus Gross GmbH & Co. KG has been active in non-destructive material testing.

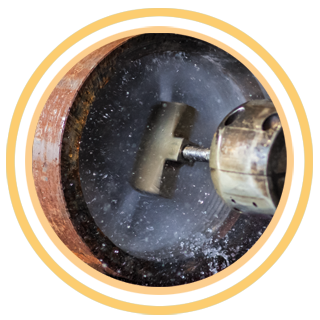

Our special pipe cleaning system enables the cleaning of pipes and drill rods up to a length of 10 meters - completely from the inside and outside.

We straighten tubes and other round materials. Diameter from 35 mm to 250 mm and solid material up to 10 m in length.